Process Capability

Guanyin Factory

Jiangyin Factory

Summary

| Parameter | Normal-MP | Advanced-MP | Limited production | |

|---|---|---|---|---|

| Layer Count | 2 - 20 Layers | 26 Layers | 34 Layers | |

| Thickness | 0.6 – 3.5mm | 0.6 – 3.5mm | ||

| Material | FR-4 | Mid. Tg/ HiTg/ HF | Ultra low loss | Rogers & hybrid material |

| Min Core | 4mil | 3mil | 2.5mil | |

| Copper | Internal | ½oz, 1oz, 2oz | 3oz | 4oz |

| External | ½oz, 1oz | 2oz | 3oz | |

| Max Shipping Size | 19.5”*22.5” (495 mm x 571 mm) | 19.9” x 23.5” (506 mm x 598 mm) | 19.9”*24.45 (506 mm x 621 mm) | |

| Max Shipping Size | PTH/ VIPPO PTH/Sequential/ 1 level HDI/ Skip via | 19.9”*24.45 (506 mm x 621 mm) | ||

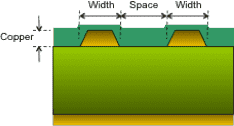

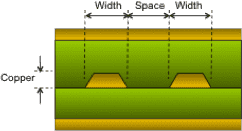

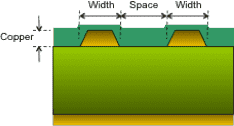

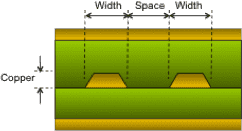

Trace Width/Space

| Parameter | Copper thickness | Normal-MP | Advanced-MP | Limited production | |

|---|---|---|---|---|---|

| Min Trace Width/Space | I/L | ½oz | 3.5/3.5mil | 3/3mil | 2.5/2.5 |

| 1oz | 3.5/3.5mil | 3/3mil | 2.5/3 | ||

| 2oz | 6/6mil | 5/5mil | 4.5/5 | ||

| 3oz | 10/10mil | 8/8mil | |||

| O/L | ½oz + plating | 3.5/3.5mil | 3/3mil | 2.5/3 | |

| ½oz + plating (VIPPO) | 4/4mil | 3.5/3.5mil | 3/3.5 | ||

| 1oz + plating | 6/6mil | 5/5mil | |||

| 2oz + plating | 8/10mil | 6/8mil | |||

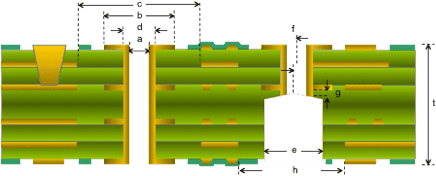

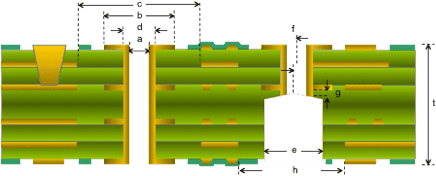

Drilling

| Parameter | Normal-MP | Advanced-MP | Limited production | |

|---|---|---|---|---|

| Layer Count | Min FHS (a) | 8mil | 6mil / 4mil | Skip via (10 mil) |

| Min DHS (d)* | 9.8mil | 7.9 mil / 6mil | Skip via (12 mil) | |

| Min Ring (b) | d+10mil | d+8mil | d+6mil | |

| Min AntiPad (c) | d+20mil | d+18mil | d+16mil | |

| Material | Min FHS | 4 | 4 | |

| Min Ring | D+8 | D+6 | ||

| Copper | Min FHS | 10 | ||

| Min Ring | d+10 | |||

| Max Shipping Size | BDHS (e) | d+8mil | d+6mil(CCD) | |

| Stub Length (g) | 7±5mil | 6±4mil | 5±3mil | |

| Accuracy (f) | ±4mil | ±3mil(CCD) | ||

| Back Drill Clearance (h) | d+20mil | d+18mil(CCD) | d+16mil (Vacuum plugging) |

|

Plating Aspect Ratio

| Parameter | Normal-MP | Advanced-MP | Limited production | |

|---|---|---|---|---|

| PTH | Max A/R (Board thickness/ Min finish hole size) | 10.5 (63 mil /6 mil) 12.5 (100 mil / 8 mil) 12.5 (125 mil/10 mil) 10 (260 mil/26 mil) | 10.5 (63 mil /6 mil) 12.5 (100 mil / 8 mil) 12.5 (125 mil/10 mil) 10 (260 mil/26 mil) | 16.7 (100 mil/ 6 mil) 20 (160 mil/ 8 mil) 20 (200 mil/10 mil) 16 (260 mil /16 mil) |

| Micro & Skip Via | 0.75 (3mil/4mil) & (7.5mil/10 mil) | 0.8 (3.2mil/4mil) & (8mil/10 mil) | ||

| Aspect ratio | 16.7 |

|---|---|

| Board thickness | 100mil |

| FHS | 6mil |

| DHS | 7.9mil |

| Aspect ratio | 15 |

|---|---|

| Board thickness | 120mil |

| FHS | 6mil |

| DHS | 7.9mil |

| Aspect ratio | 16.7 |

|---|---|

| Board thickness | 100mil |

| FHS | 6mil |

| DHS | 7.9mil |

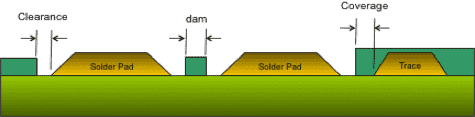

Soldermask / Legend

| Parameter | Normal-MP | Advanced-MP | |

|---|---|---|---|

| Soldermask | Color | Green / Blue Red / Yellow / Black | Low DK SM |

| Min. Dam | 3mil / 4mil(Black) | 2.5mil | |

| Min. Clearance | 2mil | 1.5 mil | |

| Min. Coverage | 2.5mil | 2mil | |

| Legend | Color | White / Yellow | Black |

| Min. Width | 5mil | 4mil / 6mil(Black) | |

Surface Finish

| Parameter | Normal-MP | |

|---|---|---|

| Soldermask | OSP | ✓ (In-House) |

| Gold Plating | ✓ (In-House) | |

| ENIG | ✓ | |

| IMAg | ✓ | |

| HASL | ✓ | |

| Selective ENIG | ✓ | |

| IMSn | ✓ | |

| LF HASL | ✓ | |

Tolerance

| Parameter | Normal-MP | Advanced-MP | Limited production | |

|---|---|---|---|---|

| Registration | Core | 2.5mil | 2mil | 1.5mil |

| D2M | 5mil | 4.5mil | 4mil | |

| Tolerance | Impedance | ±10% | Inner layer + 8% Outer layer + 10% | Inner layer + 7% Outer layer + 10% |

| Dimension | Routing:±8mil | Routing:±5mil | ||

| V-Cut:±10mil | ||||

| Thickness | ±10% | ±8% (1.6mm↑) | ||

| PTH | ±3% | ±2mil | ||

| NPTH | ±2% | ±2mil | ||

Conventional Capability Summary

| Parameter | 2020 | 2021 | ||

| MP | Sample | |||

| Max. Layer count | 16 L | 18-22 L | 24-28 L | |

| Board thick. | 0.4~3.0mm | 3.0~3.3mm | 3.2~4.0mm | |

| Material | FR-4 | Std-Loss、Mid- Loss、Low loss:(Mid. Tg/Hi.Tg/HF) | Std-Loss、Mid- Loss、Low loss、Very low loss:(Mid. Tg/Hi.Tg/HF) | Ultra low-loss |

| Min Core | 75um | 63.5um | 63.5um | |

| copper | Inner | ½oz, 1oz , 2oz,3oz | ½oz, 1oz , 2oz, 4oz | 5oz |

| Outer | ½oz, 1oz, 2oz | ½oz, 1oz, 2oz, 3oz | 4oz | |

| Max Shipping Size | 16”*19.2” (406 mm x 483 mm) | 16x 21” (406mm x 533 mm) | 16x 24.45” (406mm x 621 mm) |

|

| Parameter | 2020 | 2021 | |||

| MP | Sample | ||||

| Trace/Space | I/L | ½oz | 75/75um | 63.5/75um | 63.5/63.5um |

| 1oz | 75/89um | 63.5/75um | 63.5/75um | ||

| 2oz | 100/150um | 75/127um | 75/127um | ||

| 3oz | 200/250um | 200/250um | 150/200um | ||

| O/L | ½oz + plating | 75/75um | 63.5/75um | 63.5/75um | |

| 1oz + plating | 100/150um | 75/127um | 75/127um | ||

| 2oz + plating | 250/250um | 200/250um | 200/200um | ||

| 3oz + plating | 300/300um | 300/300um | 250/250um | ||

| Parameter | 2020 | 2021 | ||

| MP | Sample | |||

| Drill(PTH) | Min FHS (a) | 200um | 150um | 150um |

| Min DHS(d) | 250um | 200um | 200um | |

| Min Ring (b) | d+250um | d+200um | d+200um | |

| Min AntiPad (c) | d+400um | d+380um | d+380um | |

| Max A/R of FHS (t/a) | 10:1 | 12:1 | 12:1 | |

| Max A/R of DHS (t/d) | 8:1 | 10:1 | 12:1 | |

| Back Drill | BDHS (e) | d+200um | d+150um(CCD) | d+150um(CCD) |

| Stub Length (g) | 178±125um | 150±100um | 125±75um | |

| Accuracy (f) | ±100um | ±75um(CCD) | ±75um(CCD) | |

| Back Drill Clearance (h) | d+500um | D+460um(CCD) | d+356um (Vacuum plugging) | |

| Min Back Drill Pitch | 760um | 700um | 660um | |

| Parameter | 2020 | 2021 | ||

| MP | Sample | |||

| Solder mask | Color | Green / Blue Red / Yellow / Black | Custom | Custom |

| Min. dam | 75um/100um(Black) | 63.5um/ 75um (Black) | 63.5um/ 75um (Black) | |

| Min. Clearance | 50um | 37.5um | 37.5um | |

| Min. Coverage | 56um/69um(Black) | 50um/63.5um(Black) | 50um/63.5um(Black) | |

| Thickness (On the circuit) | 10um~36um | 7.5um~28um | 7.5um~28um | |

| Legend | Color | White / Yellow / Black | Custom | Custom |

| Min. Width | 100/150um(Black) | 100/ 127um(Black) | 100/ 127um(Black) | |

| Tolerance | Impedance | ≧50ohm,10%; ≦50ohm,+/-5ohm | ≧50ohm,8%; ≦50ohm,+/-5ohm | ≧50ohm,8%; ≦50ohm,+/-4ohm |

| Thickness | ±10% | 8% | 8% | |

| Dimension | Routing:±127um | Routing:±100um | Routing:±100um | |

| V-Cut:±127um | V-Cut:±127um | V-Cut:±127um | ||

| PTH | ±75um | ±50um | ±50um | |

| NPTH | ±50um | ±37.5um | ±50um | |

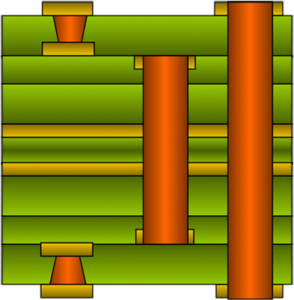

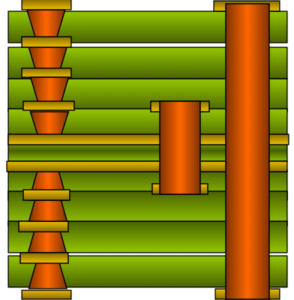

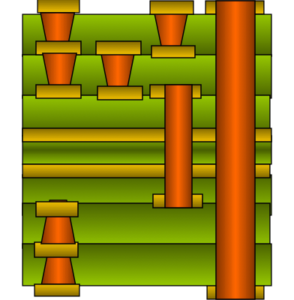

Capability / Stack up

| Stack up | |||||

|---|---|---|---|---|---|

| 1 + N + 1 |  | MP | 4+N+4 |  | MP |

| 2 + N + 2 |  | MP | 5+N+5 |  | Sample |

| 3+N+3 |  | MP | Anylayer |  | Sample |

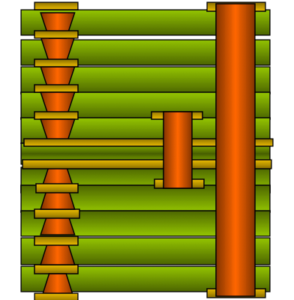

HDI Capability Summary

| Parameter | 2020 | 2021 | 2022~2023 | |

| MP | Sample | |||

| PWB Build-Up | 3-N-3,4-N-4 | Any-layer | Any-layer | Any-layer |

| Max. Layer count | 14 L | 16 L | 16 L | 18 L |

| Min. Dielectric Thick (um) | 40 | 35 | 35 | 30 |

| Min. Core Thick (um) | 50 | 50 | 40 | 40 |

| Min. Cu thickness outer layer (um) | 30 | 25 | 20 | 20 |

| Min. Cu thickness inner layer (um) | 18 | 15 | 15 | 12 |

| Min Board Thick(um) | 300 | 300 | 300 | 300 |

| Min Board Thick for 10L any-layer (um) | 700 | 600 | 550 | 550 |

| Solder Mask Registration(um) | 44.5 | 37.5 | 30 | 25 |

| Solder Mask Web Width(um) | 75 | 63.5 | 50 | 50 |

| Solder Mask thickness (um) | 20 | 17.5 | 17.5 | 15 |

| Parameter | Ref. | 2020 | 2021 | 2022-2023 | |

|---|---|---|---|---|---|

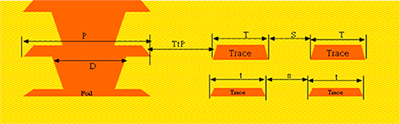

| Outer layer | μVia BGA Pad | P | 250um | 200um | 180um |

| Laser Drill Diameter | D | 100um | 75um | 63.5um | |

| Trace Width | T | 65um (25um Cu ) | 50um (20um Cu ) | 44.5um (20um Cu ) |

|

| Trace Space | S | 65um (25um Cu ) | 50um (20um Cu ) | 44.5um (20um Cu ) |

|

| Pad To Trace | PtT | 65um | 50um | 50um | |

| Parameter | Ref. | 2020 | 2021 | 2022-2023 | |

|---|---|---|---|---|---|

| Inner layer & Sub-Outer layer | μvia Pad Diameter | P | 225um | 200um | 180um |

| Laser Drill Diameter | D | 100um | 75um | 63.5um | |

| Trace Width | T | 50um (20um Cu ) | 50um (20um Cu ) | 44.45um (20um Cu ) |

|

| Space Width | S | 50um (20um Cu ) | 50um (20um Cu ) | 44.45um (20um Cu ) |

|

| Trace to Pad Space Width | TtP | 50um | 50um | 44.45um | |

| Parameter | Ref. | 2020 | 2021 | 2022-2023 | |

|---|---|---|---|---|---|

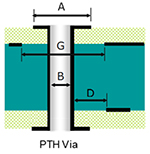

| Through Hole | Drill | B | 200um | 150um | 150um |

| Drill Pad | A | 450um | 350um | 350um | |

| Anti Pad | G | 560um | 450um | 450um | |

| Drill-Cu | D | 180um | 150um | 150um | |

Surface Finished Capability

| Parameter | MP |

|---|---|

| OSP | |

| IMAg | |

| ENIG | |

| Selective ENIG | |

| HASL | |

| HF HASL | |

| IMSn | |

| Gold Plating | |

| Carbon Ink |

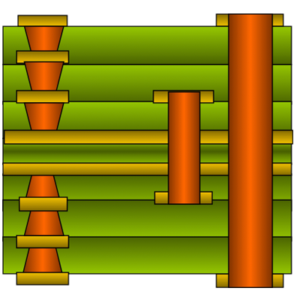

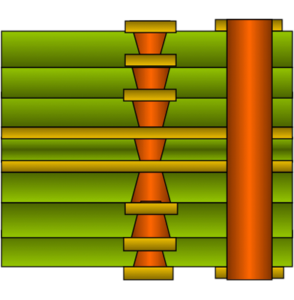

Anylayer stackup

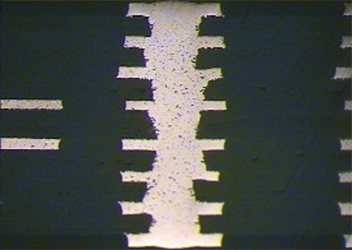

Cross-section

Reliability

| Item | Condition | Specification | Result |

|---|---|---|---|

| IST | Precondition 260℃,6cycles Thermal cycle150℃ Min200cycle | Customer spec. No delamination No crack issue Resistance deviation < 10% | Pass |

| HCT | Voltage 10 v, the temperature up to 180 ℃, duration more than 300 sec | Customer spec. No delamination No crack issue Resistance deviation < 10% | Pass |